Choosing the right alternator for your car audio system isn’t just a technical detail but it’s the key to consistent, high-performance sound. After working hands-on with hundreds of custom builds, I’ve seen how often this critical piece gets overlooked until the audio system starts underperforming. From dimming headlights to amps cutting out, the signs all point to one root cause: an alternator that simply can’t keep up.

If you’re wondering how to choose a car audio alternator, you’re already thinking like an expert. In this guide, I’ll walk you through how to calculate your system’s power demands, understand the specs that actually matter, and avoid the common mistakes people make when buying a future-ready alternator. So, let’s get started.

In This Article

- Understanding the Alternator’s Role First in Car Audio

- Calculate Your Audio System’s Power Needs

- 7 Factors to Consider When Choosing an Alternator for Car Audio

- Common Mistakes to Avoid When Buying An Alternator

- Frequently Asked Questions about Car Audio Alternators

- What happens if I choose an alternator that's too powerful for my system?

- Can a high-output alternator affect fuel efficiency or engine performance?

- How does alternator performance differ in cold vs. hot weather?

- Is there a difference between alternators for SPL builds vs. daily drivers?

- What’s the difference between OEM remanufactured and purpose-built aftermarket alternators?

- Final Note

Understanding the Alternator’s Role First in Car Audio

Think of the alternator as your system’s power plant. It generates electricity while the engine runs, keeping your amps, DSP, and accessories running smoothly. Factory alternators are built for stock needs like headlights, air conditioning, and the factory stereo. When I started building louder systems, I quickly realized those stock units couldn’t keep up. Dimming headlights, weak bass, and blown fuses usually point to one core issue: not enough amperage.

Calculate Your Audio System’s Power Needs

After understanding the role of the alternator in a car audio system, the next step is figuring out how much power your setup will actually need. Every solid build starts with a number: your system’s total current draw. Whether you’re working with a simple 600W setup or building an all-out SPL monster, here’s how I calculate it.

Determine Total RMS Wattage

Skip peak wattage claims. Only use RMS ratings. Add up the RMS output for every amplifier in your system subs, mids, highs, everything.

Convert Watts to Amps

Use the formula: Amps = Watts ÷ Voltage

If your amps total 3000 watts and your car run 13.5V power, Your alternator should be:

- 3000 ÷ 13.5 = ~222 amps

Note: When a car engine is running but not moving (idling), the alternator typically provides around 13.5 volts of electrical power to the car’s electrical system.

Then add a 25–30% buffer for system stability:

- 222 + 30% = ~289 amps

Include Base Vehicle Load

Your headlights, fuel pump, HVAC, ECU all draw current. I typically add:

- Headlights: 15A

- HVAC: 20A

- ECU/ignition: 10A

- Misc systems: 10–15A

That’s another 50–60 amps. Add it to your system draw for total demand.

Use My Automatic Alternator Calculator

To speed things up, I helped create an alternator calculator that gives a ballpark recommendation in seconds.

Inputs:

- RMS wattage

- Battery type

- Charging voltage

The result gives a minimum recommended output. It’s not your final answer, but it’s close and a great place to start.

Alternator Amp Calculator

Estimate the minimum alternator output (in amps) needed for your car audio system.

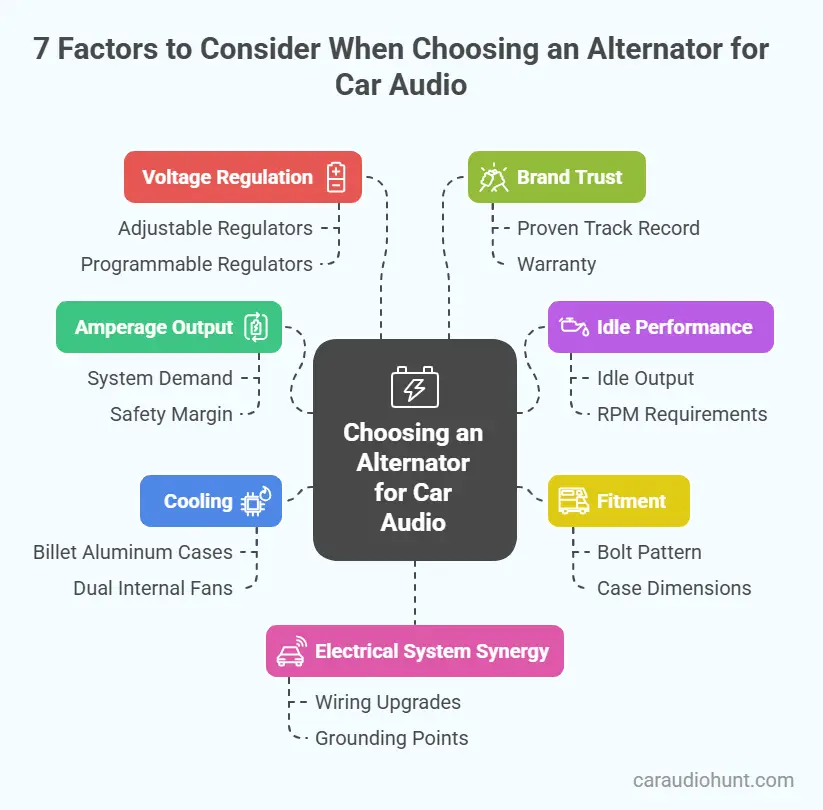

7 Factors to Consider When Choosing an Alternator for Car Audio

After calculating the right power (amps) your car audio system needs, it’s time to explore the key factors to consider when buying an alternator. The right alternator isn’t just about numbers but it’s about performance, compatibility, and long-term durability. Here’s what I personally look for when choosing an alternator that does more than just meet the specs on paper.

7 Factors to Choose an Alternator for Car Audio - Infographic

1. Amperage Output and System Demand

The first thing you must consider is the amp output in relation to your system’s demand. Amperage output is the total current an alternator can deliver at its peak performance. It’s the most direct indicator of how well your alternator can support your system’s demands. I aim for at least 25–30% above my calculated total draw to prevent strain. This extra margin handles real-world conditions like voltage drops during heavy bass hits, accessory draw on hot days, and system growth.

Choosing an alternator too close to your demand leaves no buffer and that’s when issues like dimming lights, distorted audio, or equipment shutoffs begin to show up.

2. Idle Performance Efficiency

Next, take a close look at how your alternator performs at idle. Idle output measures how much current the alternator can provide when the engine is at a low RPM. Many high-output alternators promise big numbers but under-deliver at idle, especially if they use larger pulleys or aren’t optimized for low-speed rotation.

If you demo your system at meets or while parked, this spec becomes critical. A strong alternator should deliver 60–70% of its rated power while idling. If it can’t, you’ll either drain your battery or need to raise engine RPMs just to maintain audio performance.

3. Fitment and Vehicle Compatibility

This is about more than “will it bolt in?”—it’s about whether the alternator aligns properly with your engine bay, accessory belt, and vehicle-specific mounting brackets. Larger case sizes like AD244 or CS144 are often used for high-output builds, but they don’t fit every engine compartment without modification. I always check bolt pattern, case dimensions, pulley alignment, and potential interference with nearby components. Some builds require custom brackets or belt tensioners, So fitment is never left to estimation in my builds.

4. Cooling and Build Quality

Alternators get hot especially when pushing constant high output in cramped engine bays. Cheap units with poor cooling will overheat and fail prematurely. I favor billet aluminum cases over cast housings because they dissipate heat more efficiently.

Dual internal fans, high-temp diodes, heavy-duty bearings, and copper (not aluminum) windings are all indicators of quality. Cooling isn’t just about fan count but it’s about how airflow is directed through the housing and over critical components like the stator and rectifier.

5. Voltage Regulation Features

The voltage regulator controls how much voltage your alternator sends to the battery. For high-performance or lithium battery systems, I use alternators with adjustable or programmable regulators. These let me fine-tune the output to match the charge requirements of AGM, lithium, or hybrid battery banks. Too much voltage and you risk boiling or swelling your batteries. Too little, and your system struggles to stay charged. Fixed regulators work for basic setups, but serious builds demand more control.

6. Brand Trust and Track Record

Not all alternators are created equal even with similar specs. I’ve had budget units fail early or deliver unstable voltage. That’s why I only use manufacturers with a proven track record in the audio space. Brands like Mechman, and DC Power not only build to spec, rather they offer real warranties, U.S.-based tech support, and rebuild services if something goes wrong. This is crucial when you're relying on your electrical system to protect expensive gear.

7. Electrical System Synergy

The last thing but just as critical is understanding that your alternator doesn’t work alone. It’s part of a complete electrical ecosystem that includes wiring, grounds, batteries, and fusing. Even the best alternator can’t compensate for poor infrastructure. I always recommend upgrading the Big 3 with OFC copper, using properly rated fuses based on wire gauge, and verifying clean, solid grounding points.

Without that kind of system-wide synergy, you’re opening the door to voltage drop, heat buildup, or even component failure and often, it’s not the alternator’s fault. A great alternator only performs at its best when the rest of your electrical system is built to support it. So, keep that in mind before making your purchase

Common Mistakes to Avoid When Buying An Alternator

Even seasoned installers make avoidable mistakes when buying alternators. Here are the most common I’ve seen and corrected in the field.

Underestimating Electrical Load

This is by far the most common issue. Many builders calculate amplifier wattage but overlook the vehicle’s base electrical load, things like light bars, fans, and even future upgrades. If you don’t account for everything drawing power, your system will always feel underpowered. So, keep that in mind when choosing your alternator.

Overlooking Wiring Infrastructure

I’ve seen 320A alternators connected with 4-gauge wire. That’s a recipe for resistance, heat, and failure. Upgrading wiring especially the Big 3 isn’t optional. It’s what ensures that your alternator can actually deliver its output.

Choosing Based on Price Alone

I’ve tested enough budget alternators to know this firsthand what looks like a deal often comes at the cost of performance. Cheaper units usually compromise on idle output, internal cooling, and voltage regulation accuracy. You might save some cash up front, but poor regulation can stress your amps, dim your lights, and even fry your gear. In the end, the money you “saved” often gets spent fixing problems that shouldn’t have happened in the first place.

Frequently Asked Questions about Car Audio Alternators

What happens if I choose an alternator that's too powerful for my system?

There’s no danger in going bigger as long as your voltage regulator is battery-compatible and your wiring can handle the output. Oversizing can actually help reduce heat, improve voltage stability, and future-proof your setup.

Can a high-output alternator affect fuel efficiency or engine performance?

Yes, but only slightly. The parasitic drag increase is minimal, far outweighed by the benefits of a stable electrical system. In my experience, the impact on MPG is negligible.

How does alternator performance differ in cold vs. hot weather?

From what I’ve seen in real-world installs, heat is a quiet killer. As temperatures rise, resistance increases across the entire charging system, which directly reduces output. That’s why some alternators struggle in the summer or under hood-heavy builds. I always look for high-performance models with thermal compensation or upgraded internal materials. They’re built to hold steady even when the heat is on. Cooling design isn’t just a bonus but it’s a must.

Is there a difference between alternators for SPL builds vs. daily drivers?

Definitely and it’s more than just power output. SPL builds need alternators that deliver strong idle performance and can handle serious heat from long demo sessions. I’ve run builds where idle amperage made or broke the system. On the other hand, daily drivers benefit from efficiency at varying RPMs, quieter operation, and smoother voltage regulation. Choosing the wrong type for your setup can lead to either wasted money or underwhelming results.

What’s the difference between OEM remanufactured and purpose-built aftermarket alternators?

OEM remans are stock units rebuilt to factory spec that are fine for replacement, but not high performance. Aftermarket alternators are engineered from the ground up for more amperage, better cooling, and advanced regulation. I always go aftermarket for any system pushing more than 1000W.

Final Note

At the end of the day, the right alternator is the one that works with your system not against it. When your setup is properly powered, tuned, and wired, you’re not just improving performance you’re protecting every part of your build.

It’s not about overkill; it’s about smart, stable power delivery that holds up under real-world conditions. Understanding how to choose a car audio alternator means looking beyond the numbers and making sure every part from idle output to fitment is built to support your system reliably.

If you’re ready to take the next step, check out my detailed reviews of top high-output car audio alternators to find the one that fits your setup and goals.

Some Related Guides You Might Find Helpful: